10+ Examples of IoT Sensors & How Data Is Used in 2024

IoT refers to the network of devices and other items embedded with sensors that enable these objects to collect data about their use. Find 10+ examples.

IoT sensors are not just enhancing industrial systems—they’re transforming entire sectors. Imagine the precision of a sensor that can predict a pipeline failure days before it happens, or a vibration sensor that keeps factory equipment running at peak performance without a hitch. From monitoring air quality in manufacturing plants to managing complex logistics in real time, IoT sensors have become the nerve center of modern industries. These connected devices capture critical data, unlock sensor-driven insights, and fuel innovation in ways once thought impossible. Ready to see how the invisible power of IoT sensors is shaping the future of business? Let’s dive in.

The Role of IoT Sensors in Commercial and Industrial IoT Applications

Sensor data collection has become the key to smarter commercial and industrial operations by gathering real-time data from the physical world. By gathering and transmitting real-time sensor data, these sensors, connected to Internet of Things devices, allow businesses to monitor, control, and optimize their environments with remarkable precision. Today, their role has expanded beyond basic data collection—they now drive predictive maintenance and enable more sustainable processes through sensor data analytics. As industries look to future-proof their operations, IoT sensors offer the tools to stay ahead, reducing downtime and enhancing decision-making in real time.

In commercial sectors, IoT sensors are powering smarter operations. Retailers, for instance, use temperature monitoring to manage cold storage, ensuring food safety and minimizing waste. GPS sensors track inventory and optimize fleet management, cutting down on transportation costs and improving customer satisfaction. In offices and commercial spaces, light and motion sensors help manage energy consumption, creating efficient work environments while reducing overhead. Every data point collected transforms into actionable insights, helping businesses stay agile and competitive.

The industrial sector has seen an even more profound impact. In manufacturing plants, vibration sensors detect early signs of equipment failure, enabling predictive maintenance that keeps production lines running smoothly. Chemical sensors monitor air quality in factories, ensuring compliance with stringent safety standards and protecting workers. Meanwhile, pressure sensors safeguard critical infrastructure in oil and gas, reducing the risk of costly accidents. IoT sensors allow industrial players to operate with precision, safety, and unparalleled efficiency, reshaping the future of heavy industries and accelerating digital transformation.

1. Temperature Sensors

IoT temperature sensors are among the most widely deployed IoT sensors in commercial and industrial settings. Their ability to continuously monitor and transmit data in real time makes them invaluable for several applications:

- Protecting Temperature-Sensitive Assets: In industries like food logistics, pharmaceuticals, and healthcare, IoT temperature sensors ensure vaccines, blood banks, and health samples remain within the optimal temperature range. By preventing spoilage, these sensors safeguard critical assets. Advanced applications even integrate blockchain technology to create an immutable record of temperature data, ensuring compliance with regulations and maintaining trust throughout the supply chain.

- Optimizing HVAC Systems: Traditional HVAC systems typically rely on single, hard-wired sensors to control entire rooms. IoT temperature sensors offer granular, wireless monitoring that tracks temperature variations across different zones. This results in improved control over heating, cooling, and ventilation, leading to significant energy savings. Connecting HVAC systems to industrial IoT platforms services allows businesses to optimize energy usage, detect anomalies, and ensure a comfortable environment while reducing operational costs.

- Maintaining Product Quality in Manufacturing: IoT temperature sensors are crucial in industries like food processing and chemicals, where precise temperature control is required to maintain production standards. For example, in a potato chip production line, if the frying oil temperature isn’t properly monitored, it can lead to undercooked or overcooked products, resulting in waste. By integrating IoT temperature sensors with PLC controls and SCADA systems, manufacturers can monitor these critical parameters in real time, ensuring consistency, optimizing production, and meeting regulatory requirements with minimal manual intervention.

2. Motion Sensors: Enhancing Building Management and Industrial Automation

Motion sensors are essential tools in industrial IoT, enhancing both security and automation systems. They are widely used in smart devices to enable functionalities like occupancy monitoring and security. Key applications include:

- Occupancy Monitoring in Building Energy Management Systems (BEMS): In commercial spaces such as offices or large facilities, motion sensors are used within BEMS to track how different areas are utilized. This helps optimize energy consumption by adjusting lighting, HVAC, and other systems only when spaces are occupied. This not only reduces energy costs but also contributes to more sustainable building designs, ensuring operational efficiency and lowering the environmental footprint.

- Security in Industrial Environments: Motion sensors provide an affordable and effective solution for presence detection, especially in high-security environments like manufacturing plants and warehouses. Unlike video cameras, motion sensors offer a low-cost alternative for detecting unauthorized access. These sensors can detect unusual movement after hours, triggering alerts or activating security protocols to safeguard critical infrastructure.

- Retail Applications: In retail, motion sensors are used to monitor customer traffic and footfall. This data helps optimize store layouts, manage staff, and enhance the overall shopping experience. Retailers can use motion sensor data to adjust lighting and displays, further improving customer engagement and operational performance.

- Production Floor Monitoring: On the production floor, motion sensors serve as simple on/off detectors for manual assembly lines, tracking when processes are active or idle. This data is crucial for measuring machine availability and uptime—key metrics for optimizing production efficiency. In some cases, motion sensors are attached to specific machinery, such as robotic arms or ventilators, where movement signifies activity. These insights help calculate Overall Equipment Effectiveness (OEE), providing managers with actionable data to improve operational performance and reduce downtime.

3. Environmental Sensors

Environmental sensors provide a comprehensive view of atmospheric conditions, playing a key role in industries where air quality and weather monitoring are critical. From manufacturing plants to large industrial facilities, these sensors are deployed to ensure worker safety and environmental compliance. Below are key types of environmental sensors and their applications:

- Humidity Sensors: Monitor moisture levels in the air, essential for industries like agriculture and manufacturing, where humidity control can affect product quality and machinery longevity.

- Wind Sensors: Measure wind speed and direction. These sensors are crucial in industries such as construction and renewable energy, where wind conditions can impact safety and performance, particularly for cranes or wind turbines.

- Rain Sensors: Detect rainfall levels and help adjust outdoor operations. Used in sectors like agriculture and construction, they help prevent overwatering or dangerous working conditions.

- Atmospheric Pressure Sensors: Track pressure changes that can indicate weather shifts. They are often used in logistics to optimize transportation routes or in building management to control indoor environments.

- Gas Sensors: Monitor the presence of harmful gases in industrial environments. These sensors detect dangerous emissions, like carbon monoxide or methane, to prevent accidents and ensure compliance with environmental regulations.

- Air Quality Sensors: Measure particulate matter (PM2.5, PM10) and monitor pollution levels. In manufacturing, they ensure that emissions are within legal limits and that the air quality inside factories is safe for workers. This data is essential for maintaining compliance with environmental standards and avoiding fines.

4. Soil Humidity Sensors: Revolutionizing Agriculture with Precision

Soil humidity sensors are reshaping modern agriculture by providing farmers with real-time data on moisture levels in the soil. This precision enables smarter decision-making, ensuring crops get the optimal amount of water needed for healthy growth. By tracking moisture at different soil depths, farmers can adjust irrigation systems to deliver just the right amount of water, reducing waste and conserving valuable resources.

These sensors are key to increasing crop yields. With continuous moisture monitoring, farmers can prevent both underwatering and overwatering, two factors that can negatively impact crop health. By acting on real-time data, farmers ensure that plants are growing in their ideal environment, ultimately boosting productivity and enhancing profitability.

In addition to improving yields, soil humidity sensors play a vital role in sustainable farming practices. They enable efficient water use by automating irrigation schedules, reducing water consumption, and preventing unnecessary runoff. This not only helps in regions facing water scarcity but also promotes environmental stewardship by minimizing the energy and resources needed to operate irrigation systems. Through precision irrigation, smart agriculture becomes more sustainable, productive, and resilient in the face of climate change.

5. Pressure Sensors: Ensuring Safety and Efficiency in Heavy Industries

Pressure sensors are crucial for maintaining the safety and efficiency of operations in heavy industries. By continuously monitoring pressure levels, these sensors provide real-time data that helps predict potential failures and ensure optimal performance. In industries like oil and gas, these sensors play a critical role in preventing catastrophic accidents. They detect fluctuations in pipeline pressure, identifying early signs of leaks or blockages. With immediate alerts sent to monitoring systems, companies can address issues before they escalate, avoiding costly shutdowns and environmental disasters.

In addition to the oil and gas sector, pressure sensors are widely used in water management systems. For example, they monitor water pressure in distribution networks, ensuring that water is efficiently delivered to households and industrial users. If a pressure drop indicates a leak or a pipe break, maintenance teams are notified instantly, allowing for quick repairs. This proactive approach not only conserves water but also prevents damage to infrastructure.

By integrating pressure sensors into their operations, industries can also optimize maintenance schedules. Rather than relying on fixed intervals for cleaning or servicing equipment, real-time pressure data enables a condition-based monitoring strategy. Equipment is maintained when pressure readings suggest performance is declining, reducing downtime and improving overall operational efficiency.

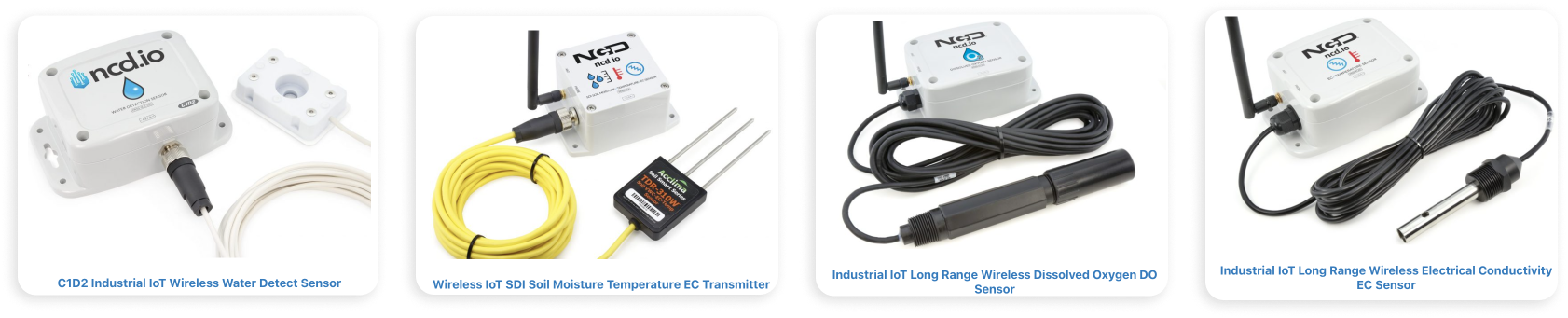

6. Water Sensors: Protecting Critical Water Infrastructure

Water sensors are vital for monitoring and managing water systems in both industrial and commercial environments. These sensors help ensure that water quality, availability, and safety are consistently maintained. Below are the key types of water sensors and their applications:

- pH Sensors: Measure the acidity or alkalinity of water, crucial in industries like water treatment, agriculture, and chemical manufacturing. Maintaining proper pH levels ensures compliance with environmental regulations and prevents damage to equipment.

- ORP Sensors (Oxidation-Reduction Potential): Track the cleanliness of water by measuring its oxidizing or reducing properties. These sensors are essential in wastewater treatment and swimming pool maintenance, where maintaining safe water conditions is critical.

- Turbidity Sensors: Monitor the clarity of water by detecting the amount of suspended particles. Often used as a proxy for water quality, turbidity sensors are commonly deployed in water treatment plants to ensure that the water being processed is safe for consumption.

- Tank Level Sensors: Provide real-time data on water levels in storage tanks, ensuring that water supplies are monitored and managed effectively. These sensors are essential in industries like agriculture, where irrigation systems rely on accurate water storage data, and in commercial buildings to monitor water reserves.

- Leak Detection Sensors for Building Management: Detect leaks in water pipes or HVAC systems, preventing water waste and structural damage. These sensors help facilities management teams respond to leaks quickly, avoiding costly repairs and conserving water resources.

- Electrical Conductivity Sensors: Measure the ability of water to conduct electricity, which is a critical indicator of water quality. High conductivity levels can indicate the presence of dissolved salts, chemicals, or contaminants, making these sensors particularly useful in agriculture, aquaculture, and industrial water treatment processes.

With these IoT water sensors in place, businesses and system integrators can safeguard critical water infrastructure, ensuring operational efficiency and compliance with environmental standards.

7. GPS Sensors: Streamlining Commercial Fleet and Asset Management

GPS sensors have long been the cornerstone of IoT, even before the term "IoT" became mainstream. These sensors, once exclusive to large-scale logistics, are now found in a wide variety of applications thanks to their reduced cost and improved accuracy. Here are some of the ways real-time location tracking is transforming commercial and industrial operations:

- Real-time Fleet Tracking for Logistics and Transportation: GPS sensors provide continuous updates on vehicle locations, helping companies optimize delivery routes, reduce fuel consumption, and enhance overall efficiency. Fleet managers can monitor drivers' progress in real time, allowing them to adjust routes based on traffic or weather conditions.

- Location-based Shipment Tracking: While not every shipment requires a GPS sensor, advances in WiFi-based GPS triangulation have enabled more granular tracking of individual packages. This is particularly valuable in high-value or time-sensitive shipments, where precise tracking can mitigate the risk of loss or delay.

- Maritime Logistics: GPS sensors are critical for tracking shipping containers across oceans. They provide real-time updates on the location of containers, ensuring that shipping companies can efficiently manage inventory, avoid bottlenecks, and keep clients informed.

- Asset Monitoring: Beyond just trucks and cars, GPS sensors are increasingly embedded into valuable assets like industrial machinery, medical equipment, and construction tools. This allows companies to track the movement of these assets, ensuring they are in the right place and properly maintained, while also safeguarding them from theft.

With the increasing availability of GPS technology, businesses are now able to manage their assets and fleets more effectively, reducing costs and improving operational visibility.

8. Proximity Sensors: Enhancing Precision in Industrial Operations

Proximity sensors, unlike motion sensors, can detect the presence of objects without physical contact and measure the exact distance to those objects. These sensors are critical in industries where precision and automation are key, enabling more efficient control over processes.

- Tank Level Tracking: In industries such as agriculture, manufacturing, and water management, proximity sensors are used to monitor tank levels. By measuring the distance between the sensor and the liquid in a tank, these sensors provide real-time data on fluid levels, allowing businesses to automate refilling processes, prevent overflows, and ensure a consistent supply of materials.

- Distance Measurement in Machinery: Proximity sensors are also widely used in industrial machinery and automation systems. They can track the position of machine parts, ensuring that moving components are correctly aligned and functioning without interruption. In manufacturing processes, proximity sensors help detect product placement, adjust robotic movements, and maintain quality control by ensuring that every component is precisely positioned before the next step in the process.

- Collision Avoidance in Automated Vehicles and Robotics: Proximity sensors are essential for preventing collisions in automated vehicles, drones, and robotic arms. By detecting the exact distance to nearby objects or obstacles, proximity sensors allow these machines to safely navigate their environment. This application is critical in warehouses, factories, and delivery systems, where avoiding collisions is crucial for operational safety and efficiency.

- Garbage Bin Monitoring: Proximity sensors are increasingly being used in smart cities applications for garbage bin monitoring. By detecting the fill level of waste bins, these sensors help optimize waste collection routes, reducing unnecessary trips and improving the efficiency of municipal waste management. This real-time data allows for dynamic scheduling of pickups, saving time, reducing fuel consumption, and ensuring bins are emptied before they overflow.

9. Optical Sensors (Including Cameras!)

Optical sensors, including cameras, have become indispensable in industrial IoT applications. These sensors enable businesses to optimize operations, enhance safety, and improve energy efficiency through real-time monitoring and automation.

- Industrial Lighting Automation for Energy Savings: Light sensors are used in commercial and industrial spaces to control lighting systems based on ambient light conditions. By automatically adjusting lighting levels in warehouses, factories, and office buildings, companies can significantly reduce energy consumption and operational costs.

- Light Sensors in Warehouses: Enhancing Worker Productivity and Safety: In addition to energy savings, light sensors help create safer and more productive work environments. By maintaining optimal lighting levels in warehouses and production areas, workers can operate more efficiently, reducing the risk of accidents caused by poor visibility.

- Cameras as IoT Sensors: Integrating live camera feeds into IoT dashboards provides unparalleled visibility over physical spaces, from monitoring production lines to overseeing entire facilities. The ability to visually assess situations in real time can improve decision-making and streamline troubleshooting processes. Cameras can also be paired with image processing techniques and machine learning in IoT to extract structured data from visual inputs, automating tasks like quality control or anomaly detection.

- Agricultural Applications with UAVs: Farmers are using unmanned aerial vehicles (UAVs) equipped with high-definition cameras to capture images of their crops from above. This data is then analyzed to detect issues such as pest infestations, irrigation problems, or soil nutrient deficiencies—well before they affect the harvest. By acting on these early insights, farmers can avoid crop failure and increase yields.

- Production Counters: Optical sensors, particularly those integrated with machine vision systems, are increasingly being used as precise production counters in manufacturing environments. By detecting and counting objects as they pass through a designated area, these sensors ensure accurate tracking of production volumes without manual intervention. Whether it’s monitoring the number of units on a conveyor belt or counting specific parts during an assembly process, optical sensing provides real-time data that enhances production line efficiency, reduces errors, and allows for better resource planning. This capability is especially valuable in industries with high throughput, where maintaining accuracy is crucial to meeting production targets.

- Thermal Cameras for Fault Detection: Thermal cameras and infrared sensors are becoming essential tools in industrial environments for detecting equipment faults and preventing costly failures. By capturing heat signatures from machinery, electrical panels, or pipelines, thermal cameras can identify areas that are overheating or experiencing unusual temperature fluctuations. Thermal cameras utilize infrared radiation to capture heat signatures, making them essential for detecting equipment faults and preventing costly failures. This early detection of potential faults allows for proactive maintenance, reducing downtime and avoiding expensive repairs. In sectors like manufacturing, energy, and utilities, thermal imaging and infrared sensors are crucial for ensuring operational safety and optimizing the health of critical infrastructure.

- Smart Cameras as Quality Inspectors: Smart cameras equipped with advanced image recognition software are now acting as quality inspectors on production lines. These cameras can automatically detect defects, inconsistencies, or deviations in products, ensuring that only items meeting strict quality standards are passed along the production process. From identifying flaws in packaging to ensuring correct dimensions and alignment, smart cameras help manufacturers maintain high product quality while minimizing waste and manual labor. This automation enhances efficiency and ensures that quality control is integrated seamlessly into production workflows.

Incorporating optical sensors into IoT solutions unlocks new possibilities for automation, efficiency, and safety across a wide range of industries.

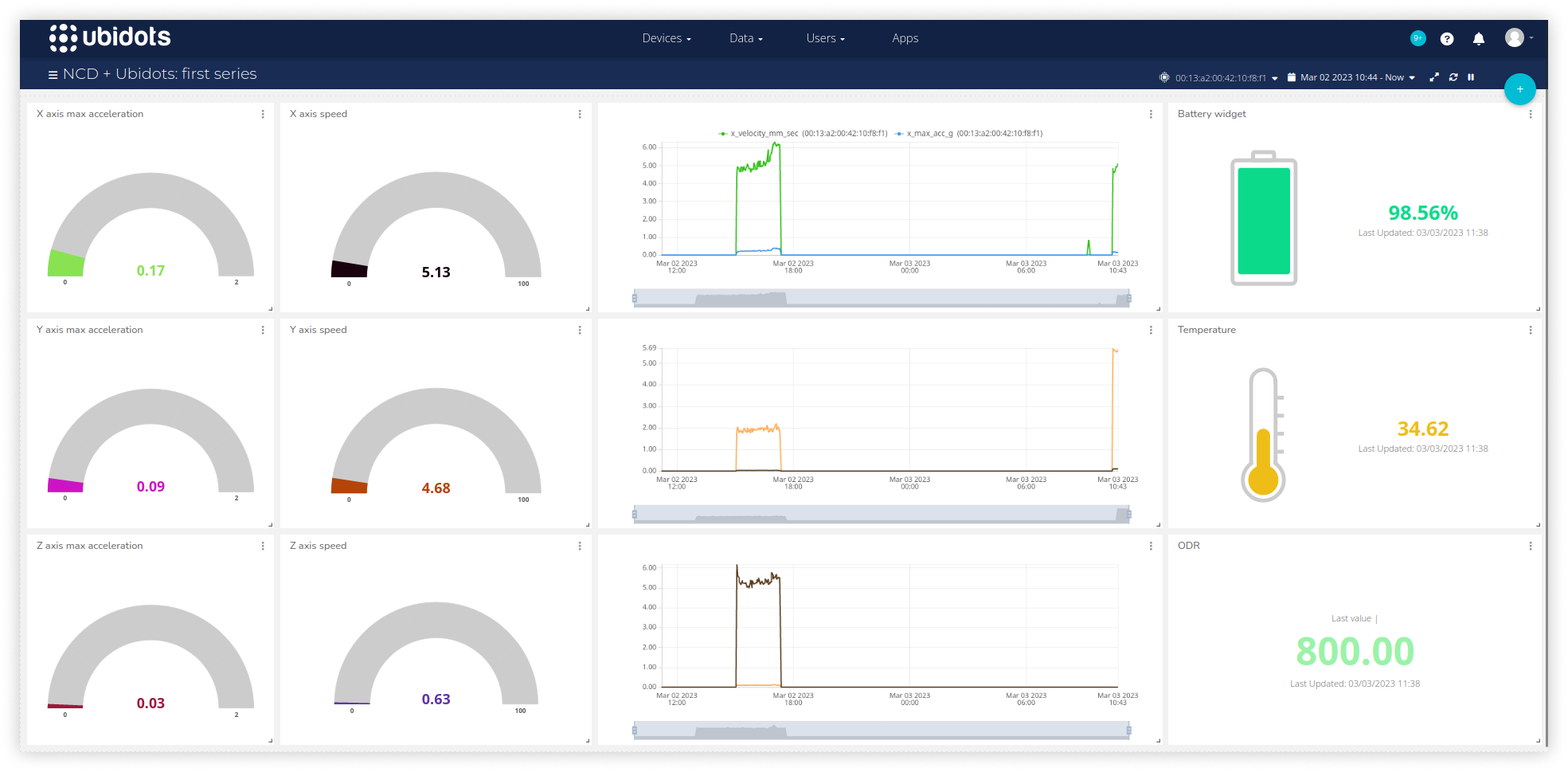

10. Vibration Sensors: Predictive Maintenance in Manufacturing

Vibration sensors play a critical role in ensuring the smooth operation of heavy machinery. By continuously monitoring the vibrations produced by industrial equipment, these sensors detect early signs of mechanical issues like misalignment, unbalance, or bearing failures. This real-time vibration analysis enables predictive maintenance, allowing manufacturers to address potential problems before they result in costly breakdowns or unscheduled downtime. For advanced analysis, IoT software can even be used to ingest and process raw vibration data. In industries such as mining, automotive, and manufacturing, vibration sensors are invaluable for keeping machines running efficiently while extending their lifespan.

In addition to fault detection, vibration sensors can monitor equipment uptime by capturing simple "ON/OFF" states. This data is essential for calculating Overall Equipment Effectiveness (OEE), a key metric for optimizing production efficiency. In scenarios where machinery is leased, vibration sensors can be used to track actual usage time for more accurate billing, ensuring that companies are invoiced only for the hours of operation. They also play a crucial role in large-scale construction projects, where equipment uptime is tied to meeting contractual obligations. By ensuring that machinery is fully operational when needed, vibration sensors help maintain project timelines and improve accountability.

11. Sound Sensors: Enhancing Safety in Industrial Workspaces

Sound sensors are becoming vital tools for improving safety and operational efficiency in industrial environments. By detecting and analyzing sound patterns, these sensors offer real-time insights into equipment health, workplace safety, and compliance with regulatory standards.

- Detecting Alarms and Machinery Malfunctions: In factories and industrial plants, sound sensors are used to detect abnormal noises that could indicate machinery malfunctions. Whether it's unusual grinding, knocking, or hissing sounds, these sensors alert maintenance teams to potential issues before they lead to breakdowns. They also act as an additional layer of safety by identifying alarm signals that may not be immediately noticeable to workers amidst the noise of production floors.

- Noise Level Monitoring for Compliance in Industrial Environments: Many industries are subject to strict regulations regarding noise levels to protect workers from long-term hearing damage. Sound sensors continuously monitor the noise in industrial spaces, ensuring that decibel levels stay within permissible limits. This helps businesses maintain compliance with health and safety regulations, and improves the overall working conditions for employees. By providing actionable data, sound sensors enable companies to take immediate steps if noise exceeds safe thresholds, such as adjusting equipment settings or providing additional protective gear for workers.

Through precise monitoring of sound, these sensors help industries maintain safety, reduce downtime, and ensure a more compliant and worker-friendly environment.

12. Chemical Sensors

Chemical sensors take IoT monitoring to a more advanced level by detecting and analyzing gases and chemicals in the environment. Unlike many IoT sensors that rely on physical transducers, these sensors are designed to interact with specific substances, such as NO₂ or CO₂, and convert these chemical interactions into electrical signals for real-time monitoring. These sensors play a crucial role in industrial settings, where exposure to harmful gases can have severe consequences for both worker safety and environmental compliance.

- Detecting Toxic Gases and Chemicals in Industrial Plants: Chemical sensors are commonly used in industries such as manufacturing, mining, and oil and gas to detect dangerous concentrations of toxic gases. These sensors help identify leaks or unsafe levels of substances like carbon monoxide (CO), nitrogen dioxide (NO₂), or methane (CH₄), triggering immediate alerts and safety protocols to protect workers and prevent environmental hazards.

- Monitoring Air Quality for Compliance: In addition to safety, chemical sensors are integral in ensuring that industrial facilities comply with environmental regulations. They continuously monitor emissions and pollutant levels, providing data that can be used to report compliance with government standards. This not only prevents fines but also ensures that companies maintain a commitment to sustainability by reducing harmful environmental impact.

With their advanced capabilities, chemical sensors are essential for industries that need to monitor potentially hazardous substances and ensure both human safety and environmental protection.

Conclusion

IoT sensors are the foundational elements driving the success of modern IoT applications. Choosing the right sensors at the outset is essential to ensure not only the relevance of your business solutions but also to manage the long-term quality and maintenance costs of the system. In this article, we explored some of the most common sensors in commercial and industrial applications, from temperature sensors in cold storage to chemical sensors for detecting harmful gases. Yet, the world of sensors goes far beyond these examples. For highly specialized requirements, there are advanced solutions like laser sensors that monitor humidity levels inside products in the food industry, ensuring precise control over product quality.

Understanding How IoT Sensor Data is Used

Regardless of the sensor type, the data collected serves as a powerful tool for optimizing operations, improving future product iterations, and predicting potential issues before they escalate into costly problems. The IoT data lifecycle typically begins with real-time collection on the device, followed by secure transmission to the cloud. From there, the data is organized and stored, with costs scaled based on the volume of data retained. It is during the final stage that sensor data analytics occurs, transforming raw data into valuable insights that businesses can act on to enhance performance, efficiency, and decision-making.

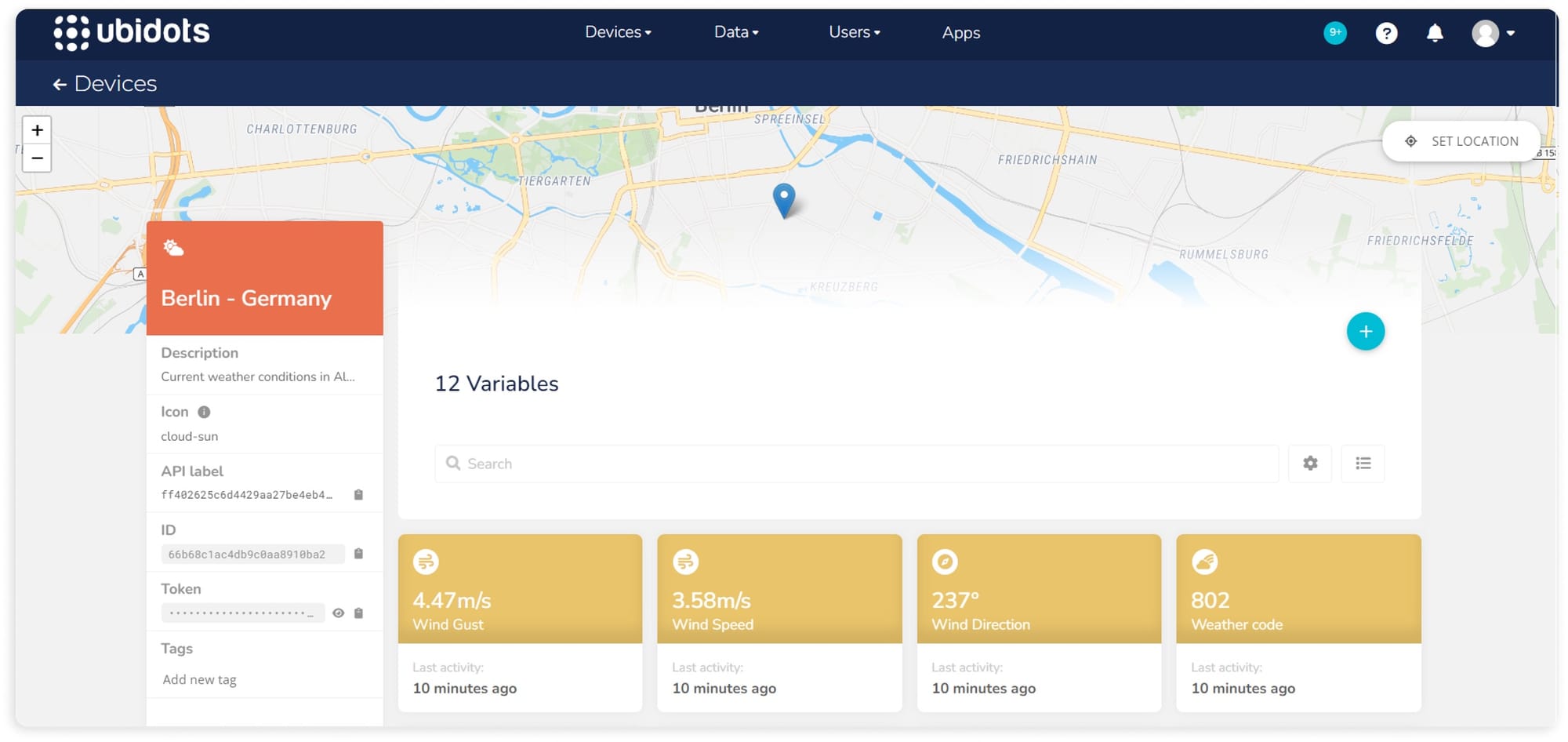

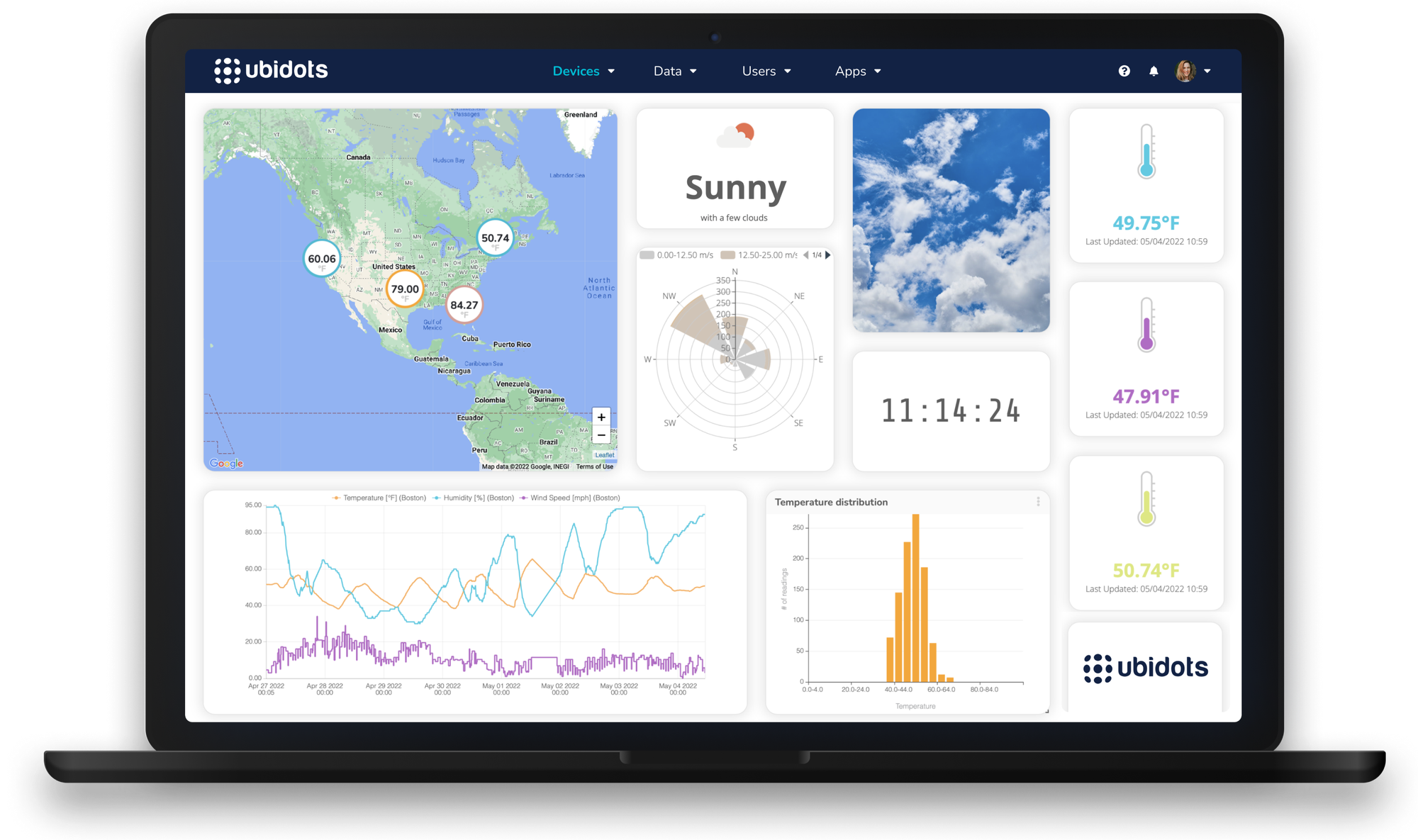

Ubidots and IoT

Ubidots is the go-to industrial IoT platform for businesses and developers alike, helping you transform raw sensor data into actionable insights. With an intuitive interface and powerful analytics tools, Ubidots enables users to quickly connect their sensors, monitor data in real time, and leverage the full potential of IoT. From manufacturing to agriculture, thousands of businesses worldwide trust Ubidots to help them harness the power of IoT. Ready to take your business to the next level? Contact us today to learn how Ubidots can help you unlock the full potential of your IoT projects.

Frequently Asked Questions

What is IoT sensor data?

It refers to the information gathered by devices within the Internet of Things (IoT). These devices, equipped with various sensors, collect data such as temperature, humidity, pressure, or motion and send it across networks for analysis and action. This seamless connectivity allows businesses to gain insights into their operations, automate processes, and make informed decisions based on real-time data.

What data do IoT sensors collect?

IoT sensors collect a wide range of data, depending on the type of sensor and its application. For example, temperature sensors measure environmental temperatures, vibration sensors monitor machine health, and GPS sensors track location. Other sensors can detect humidity levels, air quality, soil moisture, or even count the number of people in a room. Each type of sensor plays a unique role in capturing valuable information relevant to its specific environment or process.

How do IoT sensors send data?

IoT sensors are designed to be energy-efficient, often capable of operating for extended periods without the need for frequent maintenance or battery replacement. They transmit data wirelessly through various protocols, such as Wi-Fi, Bluetooth, Zigbee, or cellular networks, depending on the specific requirements of the application. The data is then sent to cloud platforms or local servers, where it can be processed, stored, and analyzed.

What can IoT sensors measure?

These sensors can measure an incredible variety of environmental and operational factors, including:

- Temperature and humidity (indoor and outdoor)

- Light intensity and UV exposure

- Air quality, including CO₂ levels, volatile organic compounds (VOCs), and particulate matter (PM)

- Water quality in terms of pH, turbidity, and other key indicators

- Soil moisture levels for precision agriculture

- Motion and acceleration for tracking movement or impacts

- Production counts and machinery uptime

These diverse capabilities make IoT sensors essential for applications ranging from industrial monitoring to environmental sustainability.

What is sensor data collection?

It involves gathering information from IoT sensors and transmitting it to a central platform for processing and analysis. This data can be used to monitor operations, detect issues, or optimize performance in various settings such as manufacturing, logistics, or environmental monitoring.

How do I collect data from IoT sensors?

Data collection from IoT sensors typically involves connecting the sensors to a cloud-based platform or local server via a wireless network. Once connected, the sensors automatically send real-time data to the platform, where it is aggregated, stored, and analyzed. Many IoT platforms provide dashboards and analytics tools to make sense of the data and turn it into actionable insights.

What are IoT sensors?

IoT sensors are devices that detect and measure changes in their environment—whether it’s a temperature sensor, motion, pressure, or air quality sensor—and convert this information into data that can be transmitted over a network. These sensors are critical components in IoT systems, enabling the automation and monitoring of various processes across industries.

What are IoT devices?

IoT devices are physical objects embedded with sensors, software, and other technologies that enable them to connect and exchange data with other devices over the internet. These devices can range from industrial machines and environmental monitors to smart meters and wearable technologies. IoT devices gather real-time data from their surroundings, which can then be processed and analyzed to automate processes, enhance operational efficiency, improve safety, and provide insights across various industries such as manufacturing, healthcare, and agriculture.

What type of data is collected from sensors?

The type of data collected depends on the specific sensor being used. Examples include temperature readings, motion detection, humidity levels, pressure changes, GPS coordinates, light intensity, air quality indicators, and water conditions. Each type of sensor collects data pertinent to its unique application, helping businesses optimize operations and ensure safety or compliance.

Where does IoT data go?

IoT data is typically transmitted to cloud-based platforms where it is stored, analyzed, and processed. This allows businesses to access their data from anywhere, gain insights in real time, and integrate the data into larger systems or applications for enhanced decision-making. Alternatively, the data may be sent to local servers if a more secure or private solution is required for specific industries or applications.